Turbo Kit Installation

#1

thanks to Emshhh at Honda-Tech for this DIY. original thread

Small update for those who are interested:

This exact setup made 238whp, 203wtq @ 10psi

my best quarter mile time is:

60'--> 2.133

330--> 5.824

1/8--> 8.773

mph--> 82.72

1000-->11.313

1/4--> 13.431

mph--> 105.17

car: 1994 white ej1

15" slips w/ falken azenis

with gsr tranny

------------------------------------------------------------------------------------------------

How to: Turbocharge a Honda

Objective:

--> I'm going to go through, step by step, procedures of what you must to do completely turbocharge your Honda. This How-to would work for all Honda/acura setups, just switch my motor setup with yours.

Pre Installation Information:

Parts Needed:

--> Turbocharger: Pick which size and trim turbo is gonna work best for your application and goals

--> Exhaust Manifold: Either log/cast/equal length. Make sure it was made for your turbo (t3, 4bolt, 5bolt, dsm, etc.)

--> Downpipe: Again must be custom for your turbo/manifold choice. A flex pipe and o2 bung are nice to have while creating a downpipe

--> Wastegate: Choose a wastegate size (also what psi spring you'd like to run) according to application such as amount of air flow and psi from turbo

--> Intercooler: Choose either a FMIC (Front Mount InterCooler) or Side Mount Intercooler. Fmic is more bling bling as well as better cooling

as well as better cooling

--> Blow off valve: This is acutally an opional (but very recommended part). Doesnt really matter which one you choose. Pick a sound you like

--> Fuel Manegment: One of the most important parts on your turbocharged car. I would highly suggest running a programable chiped ecu or standalone device, but running a AFC hack controller can be used as well

--> Fuel Pump : You will probably need an upgraded fuel pump to support the added fuel consumption. Can be either internal or external

--> Injectors : To support added air induction, more fuel is need... hence bigger injectors. Buy size according to application

--> Map Sensor: Stock maps can only read up to ~10.63 psi, if you plan to go higher upgrade to a 2bar or 3bar map sensor

--> Intercooler Piping: You can buy a ic piping kit, but usally will always take some modification to fit your exact application

--> Couplers/t-bolts: You will need silicone couplers to bind the two ic pipes together as well as t-bolts (or screw clamps which i dont recommend) to tighten those couplers down

--> Oil drain/feed lines: Every turbo needs oil, so you must buy an oil feed and drain line kit. ss lines are recommend

--> Vacuum Manifold: Not required but recommened to help organize vacuum lines and allow for good vacuum sources

--> Gauges: although not required, it's highly recommend so you can keep some status of motor operation. boost/oil pressure highly recommened

--> Spark plugs: Although not required, turbo temps can get high, so i recommend you step down two steps colder in your spark plugs. Also copper too

--> Reference picture:

Tools Needed:

--> Extensive Socket/Rachet Set: Metric sizes. the more variety, the less likely you wont have the socekt you need for the job

--> Extensive wrech set: Metric sizes. Racheting wrenchs are gonna work great for tight places

--> Floor jack w/ jack stands: you gotta get that car up for some things

--> Screw driver set: again, the more variety, the better

--> Dremel: You may need to cut or sand some things down, so a dremel will be perfect for the job

--> Wire strippers: Your gonna do some spliceing and wire cutting somewhere

--> Multi-meter: Not required, but it's handy to have around to troubleshoot and test wires

--> PbBlaster: This is a rust-breaking spray in a can, extremely useful for getting old rusted bolts off

Estimated Time and Skill level:

--> I Would give your self a week or more to finsih this install properly depend on how much free time you have. It will always be better to start early and have more time for cushion if unplaned things come up then to have jsut enough time planed and if something bad comes up your screwed (happened to me)

--> Skill level: I'd say a full turbo install would have to be from a 7-9 difficutly in the import world depending on your skill level. Building a motor being a 10.

Installation Proceduces:

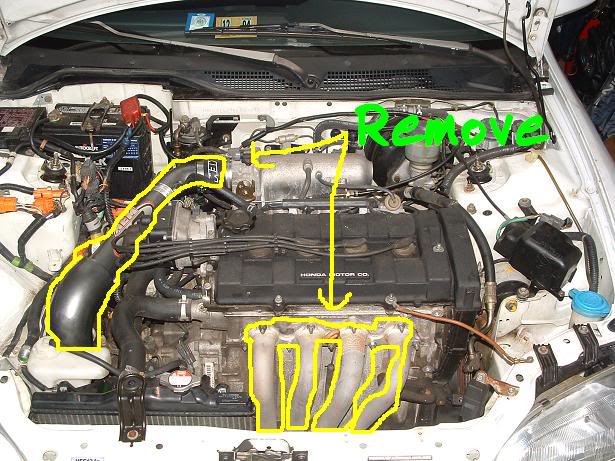

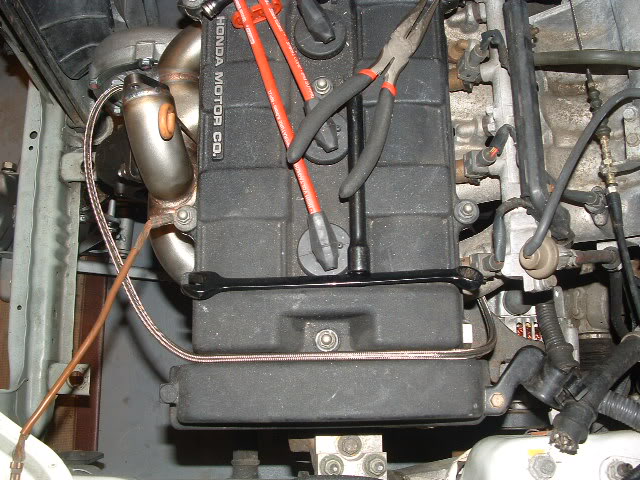

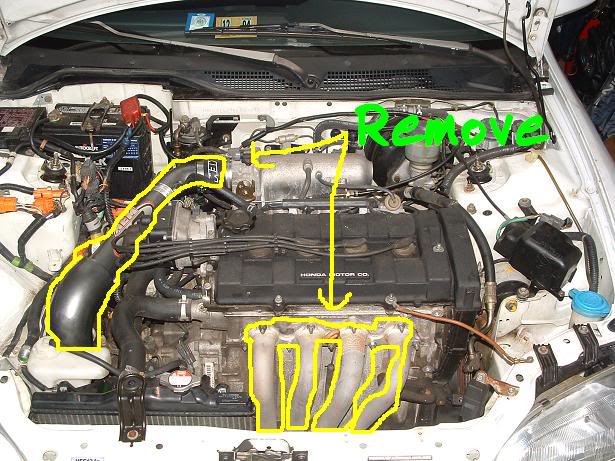

Step 1: Remove all N/a parts from your motor

--> Take a look into your engine bay and find where your Intake and header are. Since you will be replacing both with new parts, these are not needed anymore.

--> Remove Intake by unscrewing two screw clamps holding silicone coupler at the throttle body, and a bolt down near the air filter where intake is holding onto chassis.

--> Your gonna have to get under the car for the rest of this project, so it's a good idea to jack the car up and make sure to use two jack stands for safety

--> Remove 9 12mm nuts that hold header to engine head studs

--> Remove three bolts that hold cat and exhaust together. After you un bolts these three bolts, there should be two bolts that are holding header in place by a bracket hanging from the back of the block. Remove those two bolts as well and header should be free to drop out of place.

Step 2: Assemble and Install manifold/turbo/dp

--> Whether or not your bought your manifold and dp brand new or custom made it, I suggest assembling just to test fit before you try installing into the car. Check for turbo placement, and dp route.

--> First, you want to apply some Pbblaster to the o2 sensor on your n/a header, this way removal is easy. Once you get it out, screw it onto the new Dp o2 bung.

feel free to take a whif, get high lol

--> Slid the manifold on to the engine block exhaust studs

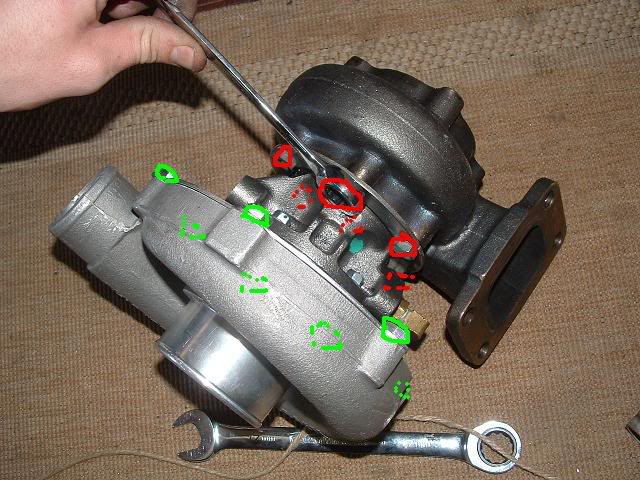

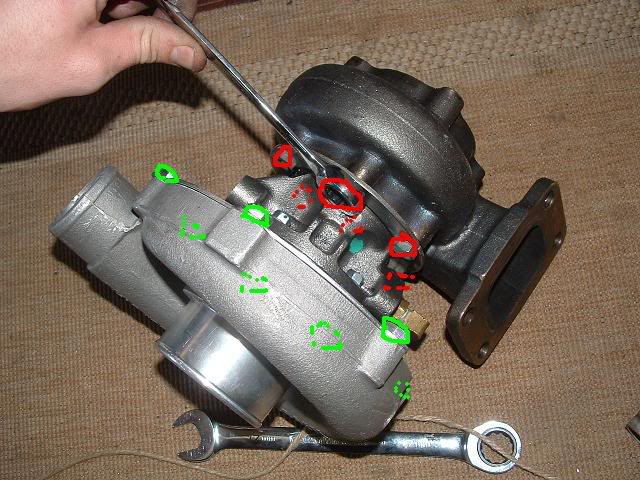

--> Next, if needed, clock your turbo to fit your setup correctly. TO clock your turbo means to rotate the compressor/turbine houseings relative to the center housing. It's easy to do, you just need to loosen the bolts that hold the housings down tight, and rotate. Tighten back up when it's in the right spot.

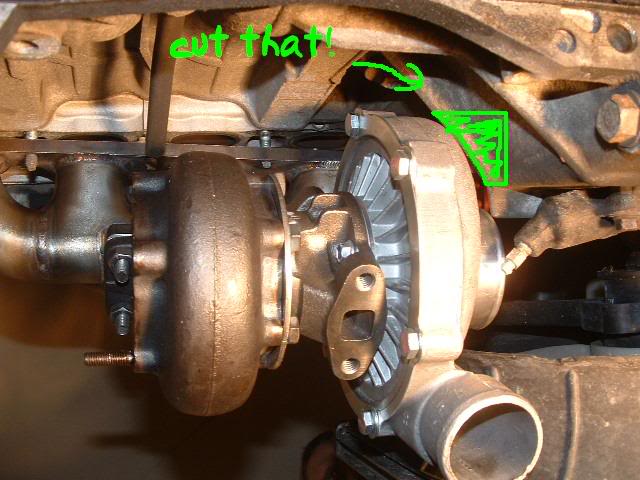

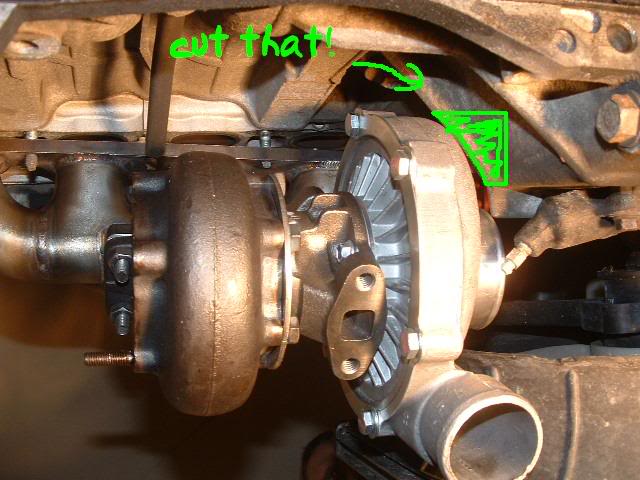

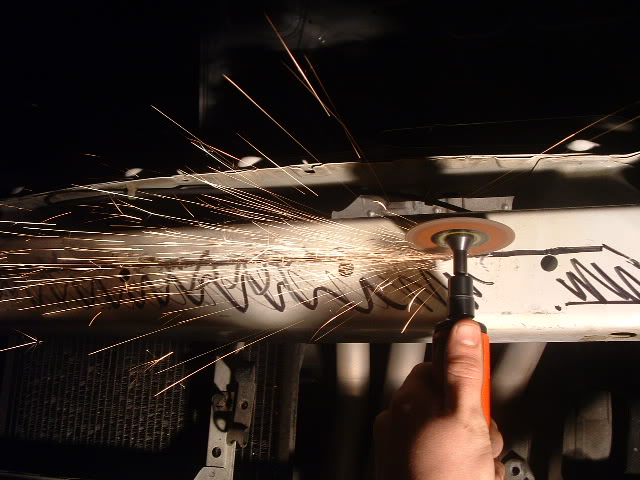

--> You now going to want to hand tight bolt the turbo to the manifold so you can test fit on the block. In this case our turbo was hitting some of the web casting on the engine block. this is actually quite common on turbo Honda's. Dont worry, the web casting isnt too hard to remove and is not that important to the structure of the block. To cut the casting, use a dremel with a cut-off wheel attatchment.

After cutting the corner off with a dremel and a cut off wheel

--> If manifold now sits flush with head of engine, and turbo is clocked to fit your setup correctly.. It's time to tighten down the head studs to hold manifold securely. Tighten turbo-->manifold bolts as well.

Step 3: Mark and Remove Oil Pan and install oil drain line

--> Get under the car and take a look at your oil pan while you have your manifold/turbo/dp on for fitment. Your gonna need to grab your oil drain line that was supplied in your oil line kit that you purchased for this step.

--> Take one end of the ss line and line it up with the oildrain hole on the turbo.

--> Take the other end, and find a way to make that line reach the designated spot on the oil pan. The spot on the oil pan can most likely be anywhere in the "deep" section of the oil pan, located at the highest point of the "deep" part. Run the line the best you can without touhcing the dp or making any sharp turns or positive slope. The oil line is important to have correct so your turbo gets effective oil cooling and lubricant for the seals. Mark where oil drain hose lines up on the oil pan with a screwdriver or something sharp so it leaves a good clear mark.

Imagine this pan still on the engine, that circle marked in yellow is the general location to where you want the oil drain line to run.

--> if there is no way to run the line without pitching, you can purchase straight/45 degree/90 degree fittings so that the line does not have a kink in it. Also, if the oil is touhcing the dp, i highly suggest you look into purchaseing some kind of heat wrap so that your oil line doesnt wear over time, as well as your "inner" rubber line doesnt melt.

--> It's got about 26 or so bolts/nuts that are holding it on.First things first, you must drain the oil from your engine so taking off the pan wont be the messiest thing you've ever done! 17mm socket to the drain plug will do the trick.

--> Once you get all the oil out, your ready to start the removal process. You first need to take off the Flywheel cover plate which is located where your transmission meets your engine block next to the oil pan.

--> After you remove that plate, 4 more bolts/nuts holding on the oil pan will be exposed. Now, you just need to remove all exsisting bolts/nuts and the oil pan should drop off freely. Make sure to keep track of oil pan gasket cus you'll need to make sure to put that on when you re-install.

--> Now it's time to either weld the oil drain bung or drill a hole for the "weld-less" oil drain that you have. Either way, it's the same concept, make a hole for oil!

--> After the hole is made, use your kit's instructions on how to install the fittings you have. Make sure to use any given rubber washers or seals so that there are no leaks. Re-install oil pan in reverse of removal.

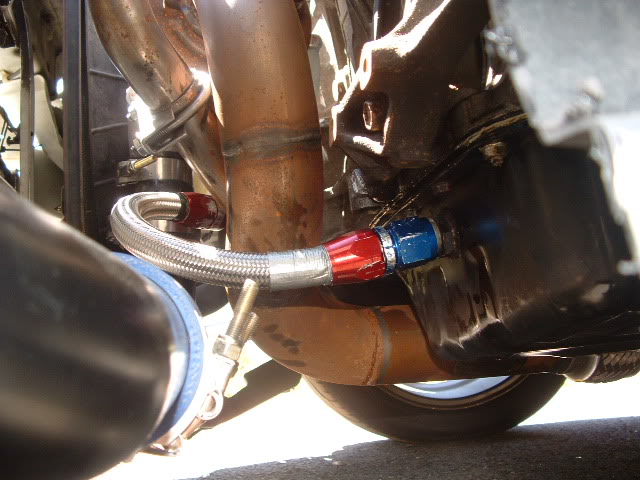

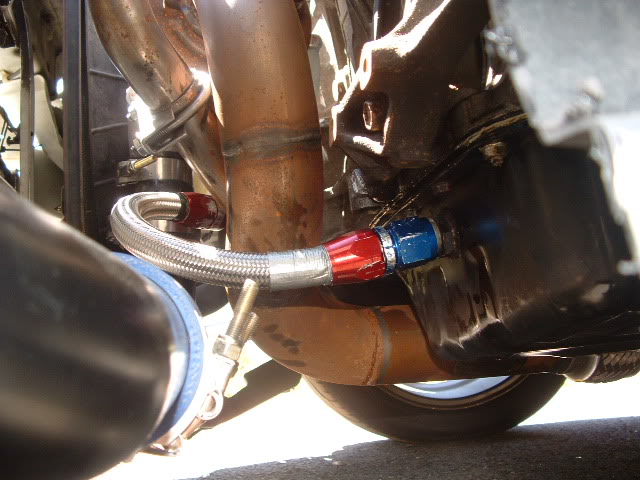

--> Find the Oil drain flange and oil drain gasket from your kit. Bolt the flange with the gasket between the flange and the turbo securely.

--> Connect the oil line from the turbo to the oil pan fitting. Make you tighten everything down so there are no leaks! Should look something like this

Step 4: Install Turbo oil Feed Line

--> Go underneath your car, as if you were going to remove the oil filter. Just left of the oil filter, you will see a black rubber plug that is running into the back of the block. This is your stock oil pressure sensor. Give it a little tug and it should snap off with alittle force.

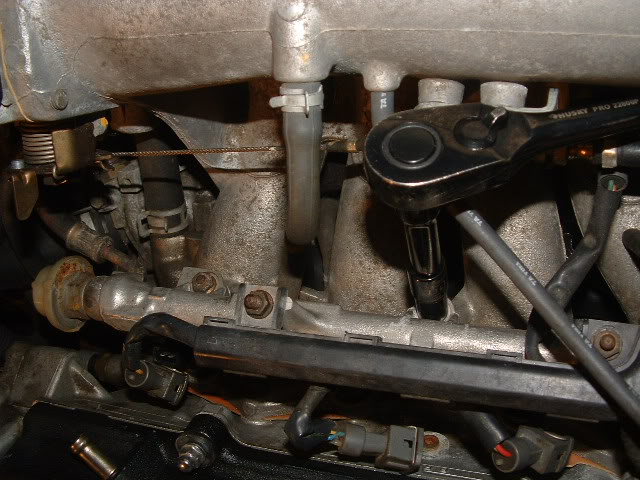

--> once the plug is unconnected, you can take a socket and rachet to remove the stock pressure sensor. It's going to be big, and a deep socket as well.. something like 21mm i believe. This is your stock sensor removed and your new "oil- T" you got in your kit.

--> With your oil T, you should have recieved a small black screw/plug to plug up a hole on the T if you do not have a need for the 2nd hole. You must plug this whole if you dont have anything to go there such as a aftermarket oil pressure sensor. In my case, i dont have one yet, so i pluged it up using a hex tool to screw it in.

--> Gently screw the Oil T into the stock oil pressure sensor hole on the block. Using a 17mm i believe it was socket, tight it down, but not extremely tight because it could crack the block if it goes in too hard. be careful. Once it's in firmly, screw the Stock sensor into the back hole of the oil T. tighten that down firmly, but not TOO tight again.

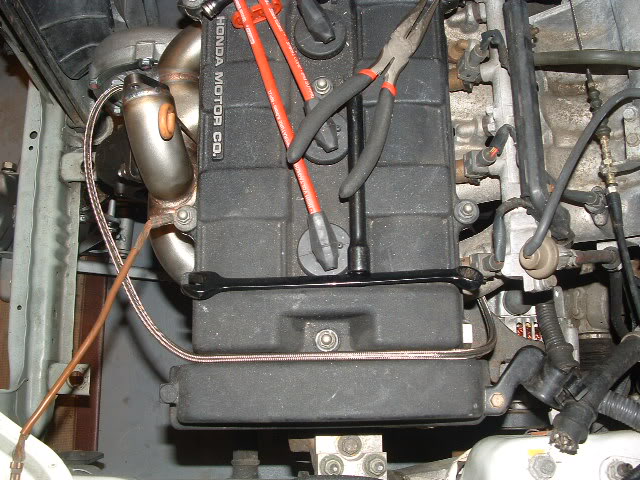

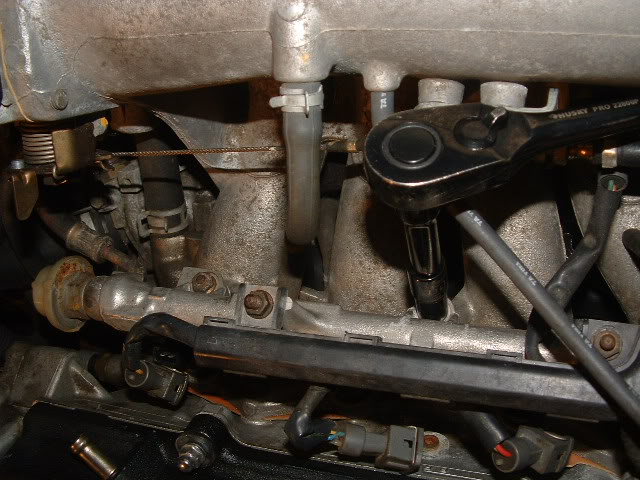

--> Now it's time to get out your oil feed line that was found in your oil kit. It should be the 3ft or so, skinny ss line. take one side and run it down to the oil T you just installed, and thread it into the last hole that is open. Again firmly but be careful.

--> It's your choice on how you run the line to get to your turbo's feed fitting. I choose to run the line through my intake manifold runners and over my vavle cover to my turbo. Thread it into the turbo and firmly tighten it down. Now your feed line is complete!

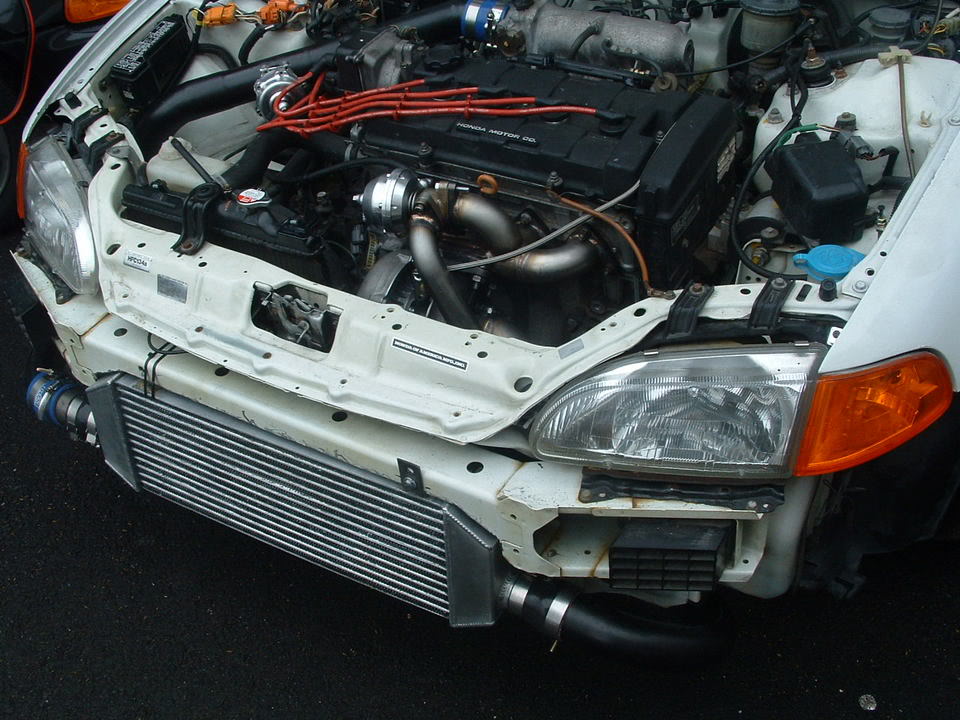

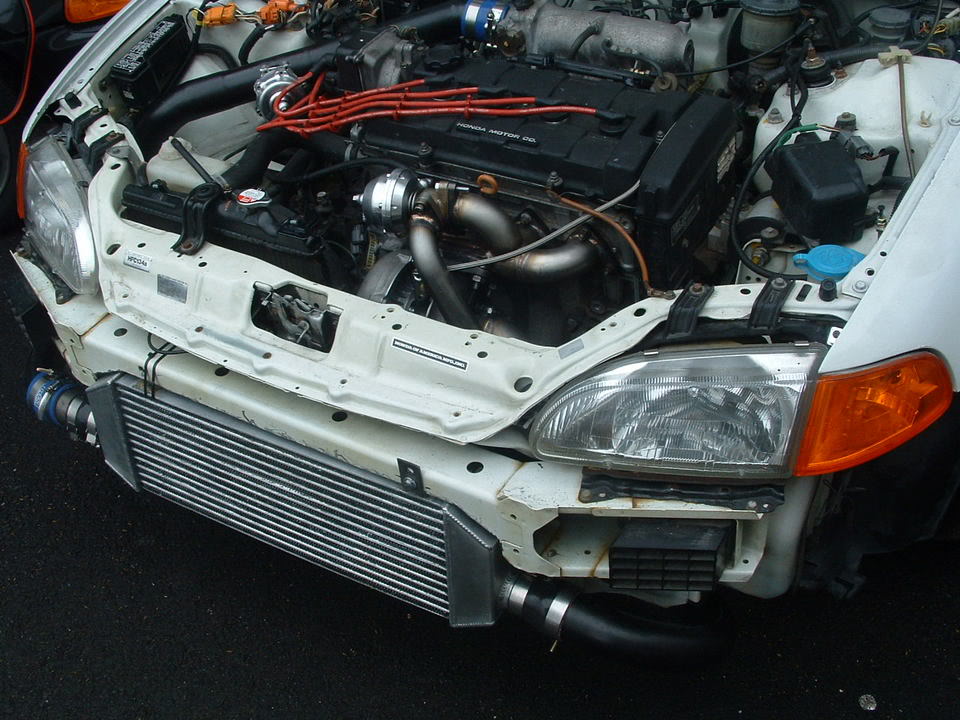

Step 4: Install Front Mount Intercooler

--> This step is really gonna vary depending on what intercooler you have choosen for your turbo kit. If you got the Johnny Racecar fmic, then all your gonna have to do is two holes and mount it up.

In my case, i have a larger Spearco which involves some modification of the bumper support. First thing your gonna have to do is take off the front bumper which isnt hard at all. there are 5 bolts up on the top of the radiator support which you need to remove. Their are two bolts(one on each side) within the fender wheel that hold bumper to fenders. And lastly, their are about 8 screws that hold all the splash gaurds to the bumper which you need to unscrew and pop out.

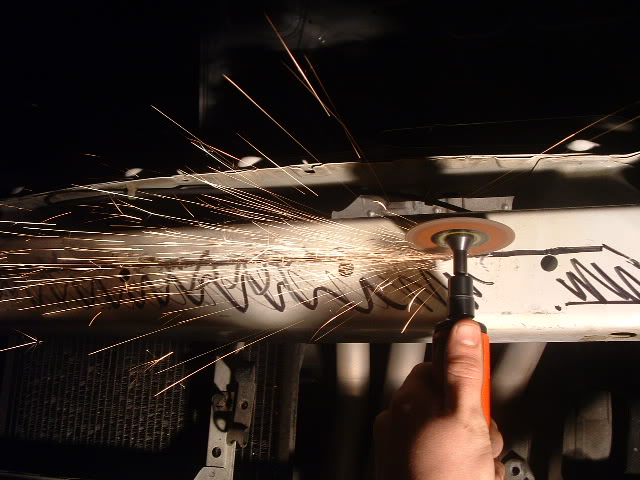

--> To do this modification, your gonna need some kind of metal cutting tool. I choose a dremel with a cut-off wheel because that's all i had in my garage. If your gonna use a dremel expect this too take 2-3hrs... I've heard of ppl using special metal recipricating saws and also hi-powered "cut-off wheels".

If you have one of those, it'd speed up the process probably, but surely aren't required. You're gonna wanna ware eye protection for this, cus little metal bits go flying everywhere!

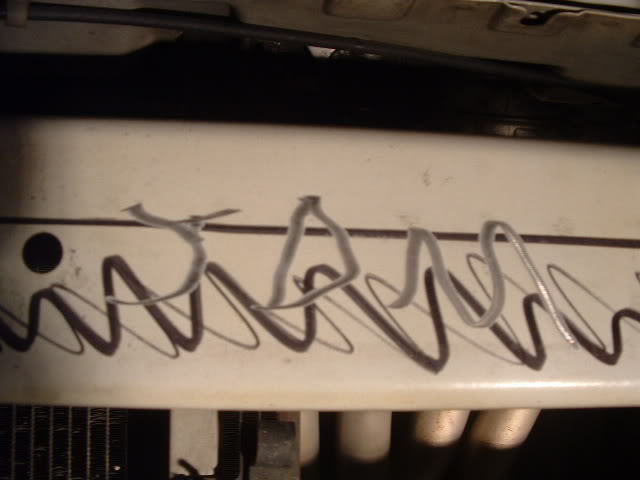

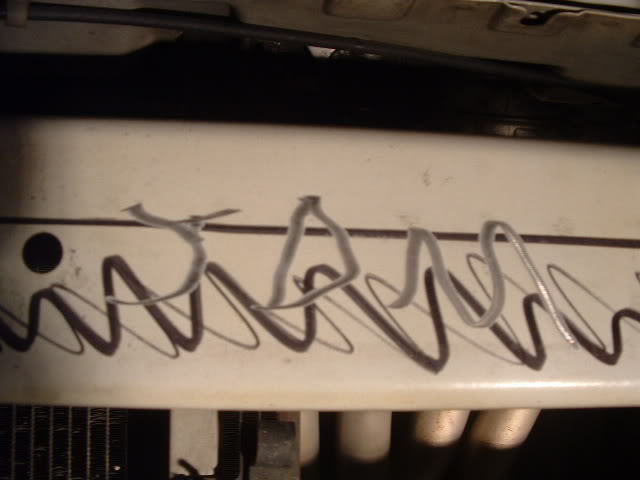

--> I first did a test fit to see what i really needed to have cut off my bumper support to allow fitment of the fmic. I held the fmic with a jack and kinda "eye-d" what woudl be needed to cut off, marked it with a sharpie. The original test fit with bumper and no cutting showed me that my fmic was about two inches lower, so i went two inches up into the bumper support

--> Now that you marked it, you just gotta start cutting away. I found it easiest to start real softly untill you got a complete hole through a small section of the metal. Once you can fit the whole cut-off wheel through and start cutting through the metal from the side, it starts to get alittle easier. I took these pics by hitting the timer button, running over to dremel, and started cutting lol. And yes, i am taking a pic with one hands and using a dremel cut-off wheel to cut my front bumper support at the same time

Alittle fun with the dremel lol

--> once you get all the way through all the metal, it should look something like this....

--> You now can mark where the holes on the ic mounts are in relation to the bumper support, then drill those marks out. Go buy some bolts/nuts/washers from homedepot to put in those newly drilled holes. sry no pics of it offically mounted.

Step 5: Modify Bumper to fit FMIC

--> Now that you have your fmic you can test fit your bumper again. It's not gonna fit without alittle cutting of the black grill. In my situation, it was easier to just cut the whole front grill out instead of trying to just cut some and save it. I aslo had to cut some of the side grill things out to fit my piping. Here's what it looks like when you begin....

--> Again you can use a dremel with a cut-off wheel adaptor to cut this off which works pretty good but you have to go slow cus it tends to melt from heat. You can also use a hack saw but dremel is more accurate. Once you got it all cut out, it should look like this.

here is the one-half of the side grill i had to cut out.

--> once you got it cut out, try it out and see how it looks! teh win!

--> With some of the piping on it had to cut some of the splash gaurd. this was not hard at all, just line it up, eye it where you need to cut, and use the dremel again to cut what is needed to be removed. should look something like this...

before:

after:

--> If it fits without hitting the fmic and all holes line up, then bolt it back up. 5 botls up top, both fender screws, and ~6 splash gaurd bolts on the bottom.

Small update for those who are interested:

This exact setup made 238whp, 203wtq @ 10psi

my best quarter mile time is:

60'--> 2.133

330--> 5.824

1/8--> 8.773

mph--> 82.72

1000-->11.313

1/4--> 13.431

mph--> 105.17

car: 1994 white ej1

15" slips w/ falken azenis

with gsr tranny

------------------------------------------------------------------------------------------------

How to: Turbocharge a Honda

Objective:

--> I'm going to go through, step by step, procedures of what you must to do completely turbocharge your Honda. This How-to would work for all Honda/acura setups, just switch my motor setup with yours.

Pre Installation Information:

Parts Needed:

--> Turbocharger: Pick which size and trim turbo is gonna work best for your application and goals

--> Exhaust Manifold: Either log/cast/equal length. Make sure it was made for your turbo (t3, 4bolt, 5bolt, dsm, etc.)

--> Downpipe: Again must be custom for your turbo/manifold choice. A flex pipe and o2 bung are nice to have while creating a downpipe

--> Wastegate: Choose a wastegate size (also what psi spring you'd like to run) according to application such as amount of air flow and psi from turbo

--> Intercooler: Choose either a FMIC (Front Mount InterCooler) or Side Mount Intercooler. Fmic is more bling bling

as well as better cooling

as well as better cooling--> Blow off valve: This is acutally an opional (but very recommended part). Doesnt really matter which one you choose. Pick a sound you like

--> Fuel Manegment: One of the most important parts on your turbocharged car. I would highly suggest running a programable chiped ecu or standalone device, but running a AFC hack controller can be used as well

--> Fuel Pump : You will probably need an upgraded fuel pump to support the added fuel consumption. Can be either internal or external

--> Injectors : To support added air induction, more fuel is need... hence bigger injectors. Buy size according to application

--> Map Sensor: Stock maps can only read up to ~10.63 psi, if you plan to go higher upgrade to a 2bar or 3bar map sensor

--> Intercooler Piping: You can buy a ic piping kit, but usally will always take some modification to fit your exact application

--> Couplers/t-bolts: You will need silicone couplers to bind the two ic pipes together as well as t-bolts (or screw clamps which i dont recommend) to tighten those couplers down

--> Oil drain/feed lines: Every turbo needs oil, so you must buy an oil feed and drain line kit. ss lines are recommend

--> Vacuum Manifold: Not required but recommened to help organize vacuum lines and allow for good vacuum sources

--> Gauges: although not required, it's highly recommend so you can keep some status of motor operation. boost/oil pressure highly recommened

--> Spark plugs: Although not required, turbo temps can get high, so i recommend you step down two steps colder in your spark plugs. Also copper too

--> Reference picture:

Tools Needed:

--> Extensive Socket/Rachet Set: Metric sizes. the more variety, the less likely you wont have the socekt you need for the job

--> Extensive wrech set: Metric sizes. Racheting wrenchs are gonna work great for tight places

--> Floor jack w/ jack stands: you gotta get that car up for some things

--> Screw driver set: again, the more variety, the better

--> Dremel: You may need to cut or sand some things down, so a dremel will be perfect for the job

--> Wire strippers: Your gonna do some spliceing and wire cutting somewhere

--> Multi-meter: Not required, but it's handy to have around to troubleshoot and test wires

--> PbBlaster: This is a rust-breaking spray in a can, extremely useful for getting old rusted bolts off

Estimated Time and Skill level:

--> I Would give your self a week or more to finsih this install properly depend on how much free time you have. It will always be better to start early and have more time for cushion if unplaned things come up then to have jsut enough time planed and if something bad comes up your screwed (happened to me)

--> Skill level: I'd say a full turbo install would have to be from a 7-9 difficutly in the import world depending on your skill level. Building a motor being a 10.

Installation Proceduces:

Step 1: Remove all N/a parts from your motor

--> Take a look into your engine bay and find where your Intake and header are. Since you will be replacing both with new parts, these are not needed anymore.

--> Remove Intake by unscrewing two screw clamps holding silicone coupler at the throttle body, and a bolt down near the air filter where intake is holding onto chassis.

--> Your gonna have to get under the car for the rest of this project, so it's a good idea to jack the car up and make sure to use two jack stands for safety

--> Remove 9 12mm nuts that hold header to engine head studs

--> Remove three bolts that hold cat and exhaust together. After you un bolts these three bolts, there should be two bolts that are holding header in place by a bracket hanging from the back of the block. Remove those two bolts as well and header should be free to drop out of place.

Step 2: Assemble and Install manifold/turbo/dp

--> Whether or not your bought your manifold and dp brand new or custom made it, I suggest assembling just to test fit before you try installing into the car. Check for turbo placement, and dp route.

--> First, you want to apply some Pbblaster to the o2 sensor on your n/a header, this way removal is easy. Once you get it out, screw it onto the new Dp o2 bung.

feel free to take a whif, get high lol

--> Slid the manifold on to the engine block exhaust studs

--> Next, if needed, clock your turbo to fit your setup correctly. TO clock your turbo means to rotate the compressor/turbine houseings relative to the center housing. It's easy to do, you just need to loosen the bolts that hold the housings down tight, and rotate. Tighten back up when it's in the right spot.

--> You now going to want to hand tight bolt the turbo to the manifold so you can test fit on the block. In this case our turbo was hitting some of the web casting on the engine block. this is actually quite common on turbo Honda's. Dont worry, the web casting isnt too hard to remove and is not that important to the structure of the block. To cut the casting, use a dremel with a cut-off wheel attatchment.

After cutting the corner off with a dremel and a cut off wheel

--> If manifold now sits flush with head of engine, and turbo is clocked to fit your setup correctly.. It's time to tighten down the head studs to hold manifold securely. Tighten turbo-->manifold bolts as well.

Step 3: Mark and Remove Oil Pan and install oil drain line

--> Get under the car and take a look at your oil pan while you have your manifold/turbo/dp on for fitment. Your gonna need to grab your oil drain line that was supplied in your oil line kit that you purchased for this step.

--> Take one end of the ss line and line it up with the oildrain hole on the turbo.

--> Take the other end, and find a way to make that line reach the designated spot on the oil pan. The spot on the oil pan can most likely be anywhere in the "deep" section of the oil pan, located at the highest point of the "deep" part. Run the line the best you can without touhcing the dp or making any sharp turns or positive slope. The oil line is important to have correct so your turbo gets effective oil cooling and lubricant for the seals. Mark where oil drain hose lines up on the oil pan with a screwdriver or something sharp so it leaves a good clear mark.

Imagine this pan still on the engine, that circle marked in yellow is the general location to where you want the oil drain line to run.

--> if there is no way to run the line without pitching, you can purchase straight/45 degree/90 degree fittings so that the line does not have a kink in it. Also, if the oil is touhcing the dp, i highly suggest you look into purchaseing some kind of heat wrap so that your oil line doesnt wear over time, as well as your "inner" rubber line doesnt melt.

--> It's got about 26 or so bolts/nuts that are holding it on.First things first, you must drain the oil from your engine so taking off the pan wont be the messiest thing you've ever done! 17mm socket to the drain plug will do the trick.

--> Once you get all the oil out, your ready to start the removal process. You first need to take off the Flywheel cover plate which is located where your transmission meets your engine block next to the oil pan.

--> After you remove that plate, 4 more bolts/nuts holding on the oil pan will be exposed. Now, you just need to remove all exsisting bolts/nuts and the oil pan should drop off freely. Make sure to keep track of oil pan gasket cus you'll need to make sure to put that on when you re-install.

--> Now it's time to either weld the oil drain bung or drill a hole for the "weld-less" oil drain that you have. Either way, it's the same concept, make a hole for oil!

--> After the hole is made, use your kit's instructions on how to install the fittings you have. Make sure to use any given rubber washers or seals so that there are no leaks. Re-install oil pan in reverse of removal.

--> Find the Oil drain flange and oil drain gasket from your kit. Bolt the flange with the gasket between the flange and the turbo securely.

--> Connect the oil line from the turbo to the oil pan fitting. Make you tighten everything down so there are no leaks! Should look something like this

Step 4: Install Turbo oil Feed Line

--> Go underneath your car, as if you were going to remove the oil filter. Just left of the oil filter, you will see a black rubber plug that is running into the back of the block. This is your stock oil pressure sensor. Give it a little tug and it should snap off with alittle force.

--> once the plug is unconnected, you can take a socket and rachet to remove the stock pressure sensor. It's going to be big, and a deep socket as well.. something like 21mm i believe. This is your stock sensor removed and your new "oil- T" you got in your kit.

--> With your oil T, you should have recieved a small black screw/plug to plug up a hole on the T if you do not have a need for the 2nd hole. You must plug this whole if you dont have anything to go there such as a aftermarket oil pressure sensor. In my case, i dont have one yet, so i pluged it up using a hex tool to screw it in.

--> Gently screw the Oil T into the stock oil pressure sensor hole on the block. Using a 17mm i believe it was socket, tight it down, but not extremely tight because it could crack the block if it goes in too hard. be careful. Once it's in firmly, screw the Stock sensor into the back hole of the oil T. tighten that down firmly, but not TOO tight again.

--> Now it's time to get out your oil feed line that was found in your oil kit. It should be the 3ft or so, skinny ss line. take one side and run it down to the oil T you just installed, and thread it into the last hole that is open. Again firmly but be careful.

--> It's your choice on how you run the line to get to your turbo's feed fitting. I choose to run the line through my intake manifold runners and over my vavle cover to my turbo. Thread it into the turbo and firmly tighten it down. Now your feed line is complete!

Step 4: Install Front Mount Intercooler

--> This step is really gonna vary depending on what intercooler you have choosen for your turbo kit. If you got the Johnny Racecar fmic, then all your gonna have to do is two holes and mount it up.

In my case, i have a larger Spearco which involves some modification of the bumper support. First thing your gonna have to do is take off the front bumper which isnt hard at all. there are 5 bolts up on the top of the radiator support which you need to remove. Their are two bolts(one on each side) within the fender wheel that hold bumper to fenders. And lastly, their are about 8 screws that hold all the splash gaurds to the bumper which you need to unscrew and pop out.

--> To do this modification, your gonna need some kind of metal cutting tool. I choose a dremel with a cut-off wheel because that's all i had in my garage. If your gonna use a dremel expect this too take 2-3hrs... I've heard of ppl using special metal recipricating saws and also hi-powered "cut-off wheels".

If you have one of those, it'd speed up the process probably, but surely aren't required. You're gonna wanna ware eye protection for this, cus little metal bits go flying everywhere!

--> I first did a test fit to see what i really needed to have cut off my bumper support to allow fitment of the fmic. I held the fmic with a jack and kinda "eye-d" what woudl be needed to cut off, marked it with a sharpie. The original test fit with bumper and no cutting showed me that my fmic was about two inches lower, so i went two inches up into the bumper support

--> Now that you marked it, you just gotta start cutting away. I found it easiest to start real softly untill you got a complete hole through a small section of the metal. Once you can fit the whole cut-off wheel through and start cutting through the metal from the side, it starts to get alittle easier. I took these pics by hitting the timer button, running over to dremel, and started cutting lol. And yes, i am taking a pic with one hands and using a dremel cut-off wheel to cut my front bumper support at the same time

Alittle fun with the dremel lol

--> once you get all the way through all the metal, it should look something like this....

--> You now can mark where the holes on the ic mounts are in relation to the bumper support, then drill those marks out. Go buy some bolts/nuts/washers from homedepot to put in those newly drilled holes. sry no pics of it offically mounted.

Step 5: Modify Bumper to fit FMIC

--> Now that you have your fmic you can test fit your bumper again. It's not gonna fit without alittle cutting of the black grill. In my situation, it was easier to just cut the whole front grill out instead of trying to just cut some and save it. I aslo had to cut some of the side grill things out to fit my piping. Here's what it looks like when you begin....

--> Again you can use a dremel with a cut-off wheel adaptor to cut this off which works pretty good but you have to go slow cus it tends to melt from heat. You can also use a hack saw but dremel is more accurate. Once you got it all cut out, it should look like this.

here is the one-half of the side grill i had to cut out.

--> once you got it cut out, try it out and see how it looks! teh win!

--> With some of the piping on it had to cut some of the splash gaurd. this was not hard at all, just line it up, eye it where you need to cut, and use the dremel again to cut what is needed to be removed. should look something like this...

before:

after:

--> If it fits without hitting the fmic and all holes line up, then bolt it back up. 5 botls up top, both fender screws, and ~6 splash gaurd bolts on the bottom.

Last edited by trustdestruction; 02-24-2010 at 09:36 PM.

#2

Step 6: Walbro Internal Fuel Pump Installation

--> First things first, you need to un-hook both negative/positive cables from the battery to be safe, cus life is better then death.

--> Next, fold down your back seat using the key lock located on your rear speaker pannel above rear seats. There is one bolt that is holding your backseats onto the chassis which is accessible through the trunk of your car. Feel free to get all the way in your trunk to ge this bolt with a wrench in hand.

--> Once that bolt is removed, go back to the inside of the car. Push the top part of the back seat back into it's locked position so you dont have it all in the way. Pull up toward you on the back seat farthest from you, you will see two metal clip that hold the front of the seat in position. Simply mouever the clips of out their holes and the back seat should come free to take out of the car.

Seat removed. Look at all that lost change! You'll find some wierd **** under your seat lol.

--> Now that you have the fuel tank access cover exposed, it's time to release fuel tank pressure. to do this, you should open up your gas cap, as well as relieve pressure from your fuel filter. Make sure you have good ventalation so you dont start tripping off gas fumes.

--> Releaseing pressure from the fuel filter is pretty easy. There is one "service" bolt that is threaded into the Banjo bolt on top of the fuel filter. Use a wrench to hold banjo bolt in place, while using a rachet to loosen the service bolt. Prepare for some fuel to leak out, so put a rag around the fuel filter.

--> It's time to take of the access cover, simple unscrewing of 4 screws will do the trick.

<

<

with the cover pulled up

--> Pull out the cord from the connector first

--> use a rachet to loosen the banjo bolt (prepare for small fuel leak, have rag on hand) as well as pull vaccum hose off of the nipple. Lastly, there will be 6 nuts that hold down the cover plate, remove those.

--> NOw you are ready to pull the fuel pump out of the gas tank. Pull up and at a diagonal to remove it, should just slide out like so.

--> Once you have it out of the car, it's ready to swap the old fuel pump with the new walbro fuel pump. using a flat head screw driver, gently pop off the green "safety clip" that is holding the wire plug together. Once you poped it off, unplug the connector. Make sure not to lose the green safety clip because you will need it again to reinstall.

--> Using plyers, pull the rubber hose off the nipple. NOw the fuel pump is free to come off the mount, just pull on it and it should come off( it may feel hard to come off, but that's just cus the rubber bushing makes it have a tight fit.)

--> Compare your new walbro to your Oem fuel pump to make sure everything looks the same. In my case, the company i ordered from did not send me the correct filter to for my application, so I had no choice but to re-use the stock filter.

--> For reinstallation, just do all removal backwards. snap fuel pump into mount, connect rubber hose to nipple, plug connector back into place, snap "safety clip" onto the connector, slide fuel pump down and diagonal into fuel tank, hook up rubber hose, tighten banjo bolt, plug wire connector, tighten 6 nuts to fuel plate, screw down fuel tank access plate back down tight, clip back seats back into chassis, tighten back seat bolt. COMPLETE

Step 7: Installing Dsm Injectors

-->Buy a set of dsm injectors

-->First, relieve fuel pressure just like you did while installing the fuel pump, if not relieved already.

--> Using a flat head screwdriver, you can unclip the metal wire that holds the injector clips onto the stock injectors.

--> Take a 10mm socket with an extension on it, loosen and remove the three nut that hold the fuel rail down to the manifold.

--> The fuel rail should now be able to pulled off. When the injectors slip out of the manifold, there will be two o-rings below it, make sure you dont loose them. The injectors pop right out of the fuel rail. Here is the stock injectors(brown) compared to the dsm injectors(blue)

--> Cut the two wires leading to the stock injector clips, leave enough wire on either side so that you can rewrire the stock clips back in if you need/want to.

Strip the two wires

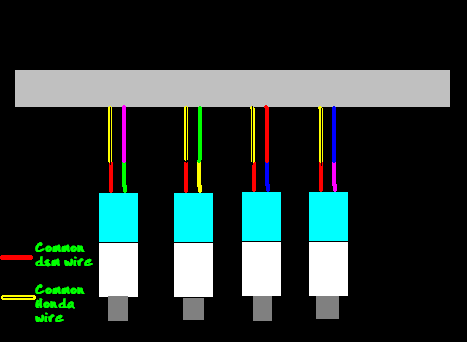

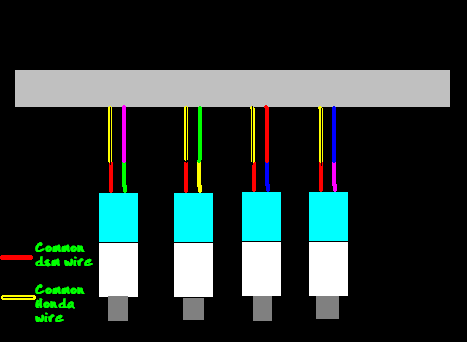

--> The four pairs wires coming off the fuel rail will have a common color of wire and one random color wire. If you look at the dsm clips, it will also have one common color wire and one random color wire.

The fuel rail has common yellow/black wire, and the dsm has common red wire. Take the common from each side, and solder them together for each clip. Then take the random wires and solder those together. order does not matter.

SOlder the wires together and use electrical tape to cover and protect the exposed wire.

-->Now that the clips are on, it's on to perparing the o-rings for installation. The tip of the injector on the dsm is wider in diameter then the stock injectors. This means you need to either buy larger o-ring injectors, or bore out the o-rings to fit.

Here is an side by side comparison of the diameter difference.

--> I decided to bore out the o-rings due to time constraint. I happened to have the perfect dremel bit to do the job.

--> I only used the larger hard o-ring because the soft ones would not work with the dremel. I HAVE NOT had any leaks by only useing large o-ring.

--> Install the injectors just like you took them out. tighten down 3 nuts to hold fuel rail in. the blue looks good.

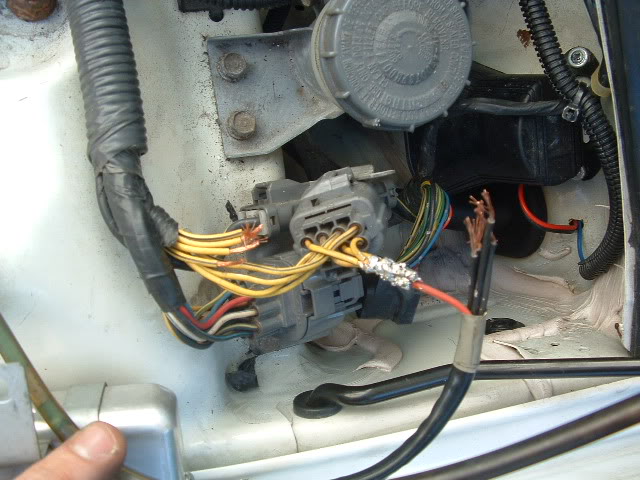

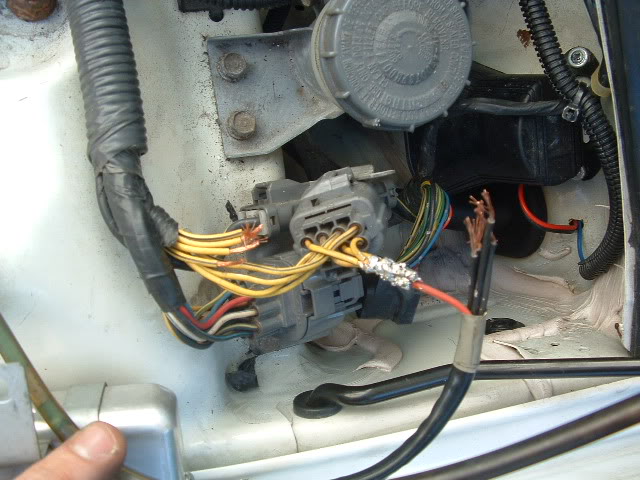

Step 8: Installing Injector Resistor Box

--> Some obd0 Honda's and some other cars use low impedance injectors which need a resistor box. You can find these at a junk yard or for cheap on ebay.

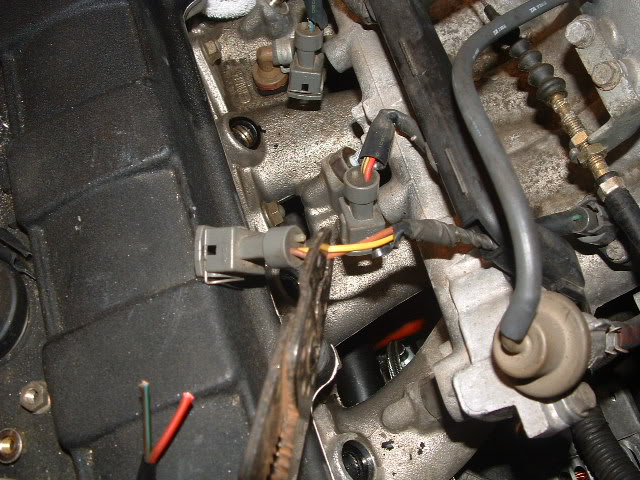

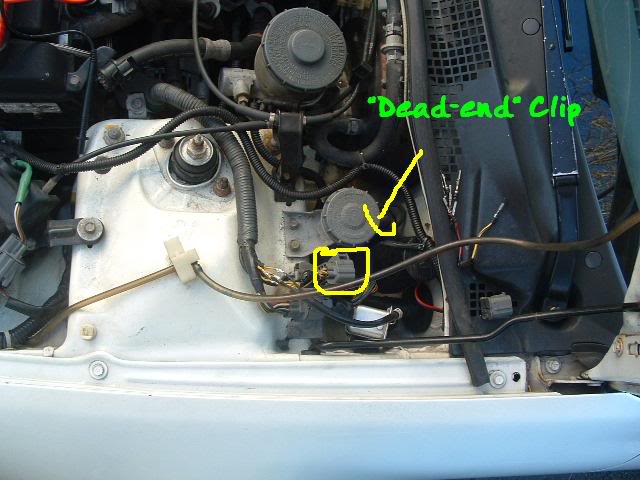

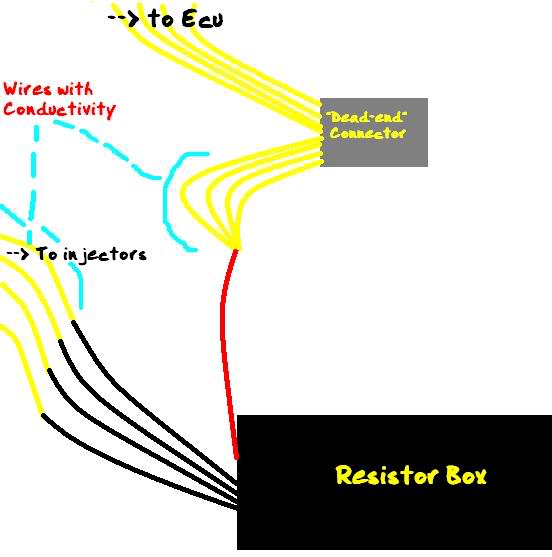

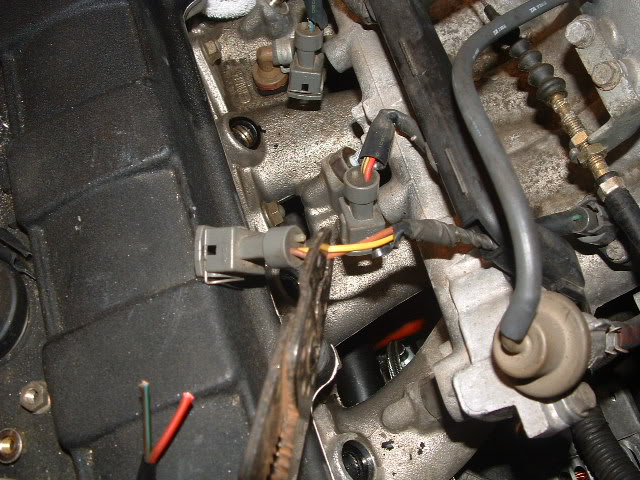

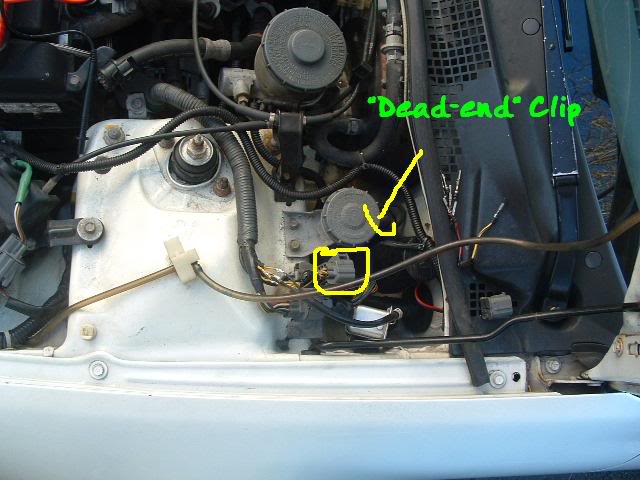

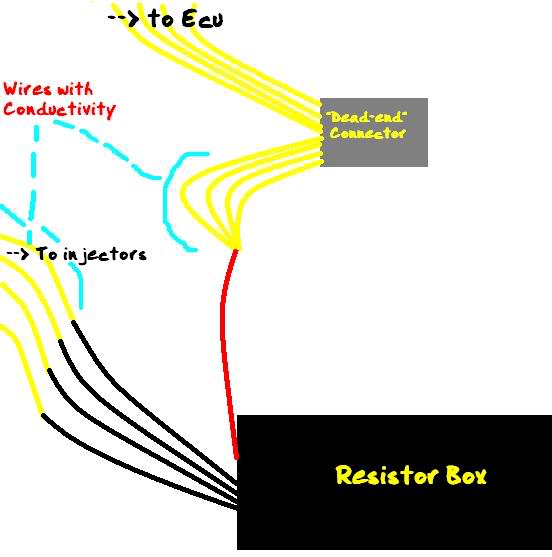

--> On obd1 Honda's, there is a "dead end" clip on the wiring harness in the right corner of the engine bay. (obd2 has this clip under the intake manifold). This clip has the electrical power running through it that goes to the injectors. It is right next to the clutch master cylinder.

When you find the clip, pop off the Protecting cover so it exposes the inside.

--> Using a multimeter, check for conductivity between each clip and the end's of the "dead-end" connector. The idea is to find which wires actually are routed to the injector clips, so seeing if electricity can flow, you can guess-and-check and find out.

There are eight different wires going into the "dead-end" connector, all of which you must check to see if they are the winners! According to h-t, it could be random placed, so do not assume and follow my example. CHECK FOR YOURSELF TO MAKE SURE!

The red dots are showing which ones came out conductive for me. AGAIN, CHECK FOR YOURSELF TO MAKE SURE!

--> Once you found out which ones are conductive, move down 2-4 inches and cut the wire. This break in to wire is where you will have your resistor tie into the system. Strip both sides of the new striped wires.

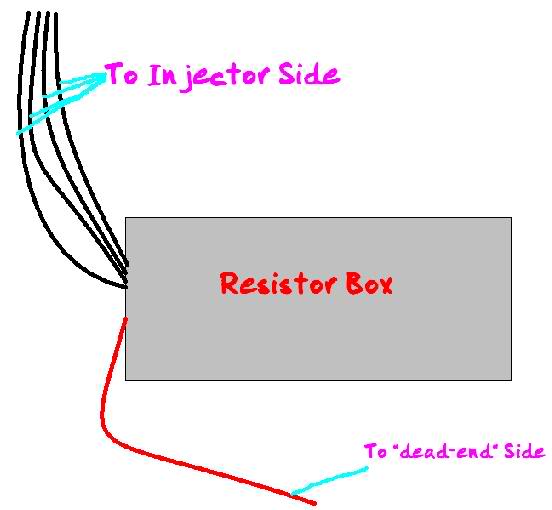

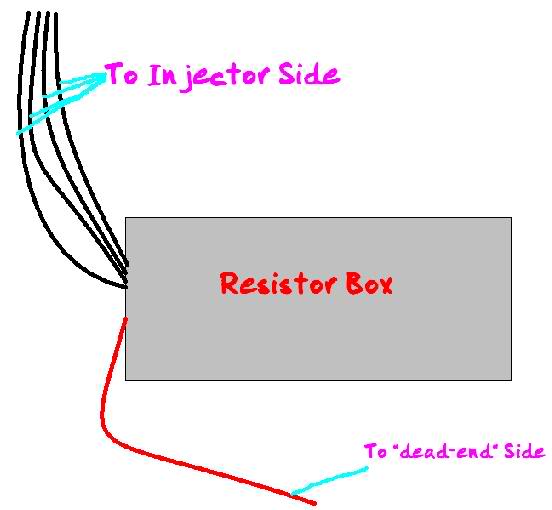

--> If you take a look at your resistor box, there should be 5 wires coming out of it. Four of them should be common color and one of them should be a different color. Strip all the ends if they are not already.

--> Next, Take the Single different color wire from the resistor box and solder it to all Four of the wires on the "dead-end" side. See diagram for better explaintion.

Connect Each one of the Four common color wires from the resistor box to one of the four yellow/black wires on the Injector side of the cut. Solder each wire seperately, no order is nessecary.

Here is a Diagram I made for better explaintion.

--> Wrap all the exposed wires up with electrical tape and mount the resistor box in the corner. here is the finished product.

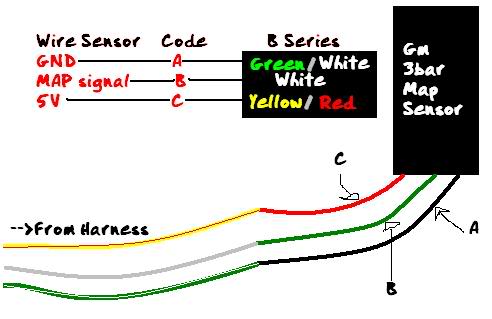

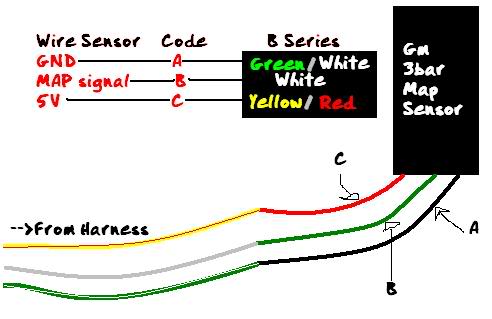

Step 9: Installing Gm 3bar Map Sensor

--> Purchase Gm 3bar Map Sensor with Pigtail connector From Camp1320.com. It's like 80$shipped new!

--> You must find stock map sensor(it is located right ABOVE throttle body). Clip off the old connector on the harness side of the sensor. Strip and get the wires ready to solder to somethign new.

--> The new Gm map sensor should have came with a "pigtail" which is the male side of the connector with wires coming out of it ready to solder together. Strip them.

--> I put together a diagrahm on how this should be wired up!

Refrence hondata.com's picture of a gm 3bar for the clip wire order...

--> Connect a vacuum hose from the map sensor to a good vacuum source. I used a GE vac manifold again for a good relieable source. You do not want to "t" this vacuum source off anything else, nor have it too long of a hose. The map sensor is sensitive and extremely important to the performance of your vehicle.

--> To check for proper installation, use multimeter to check voltages and conductivity. Between wire A and C, there should read 5volts. With ignition "on" but car not running, There should be 1.6Volts between A(GND) and B(map signal).

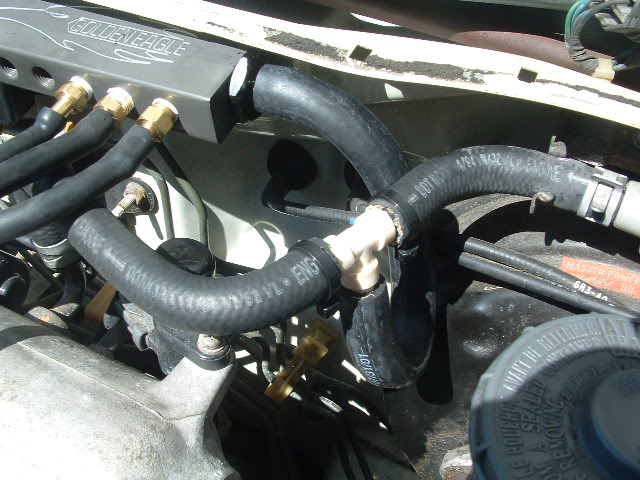

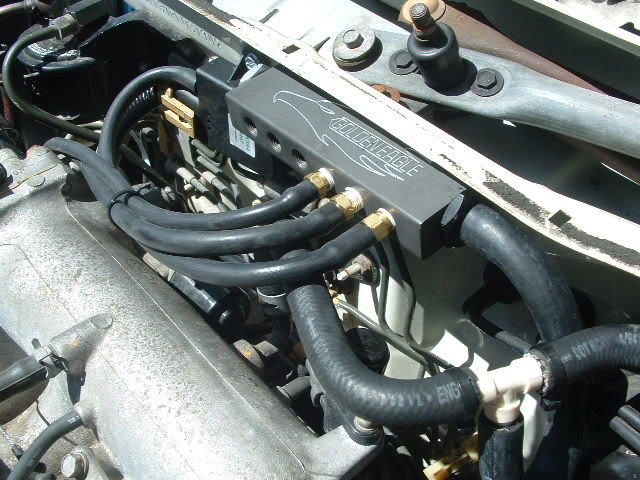

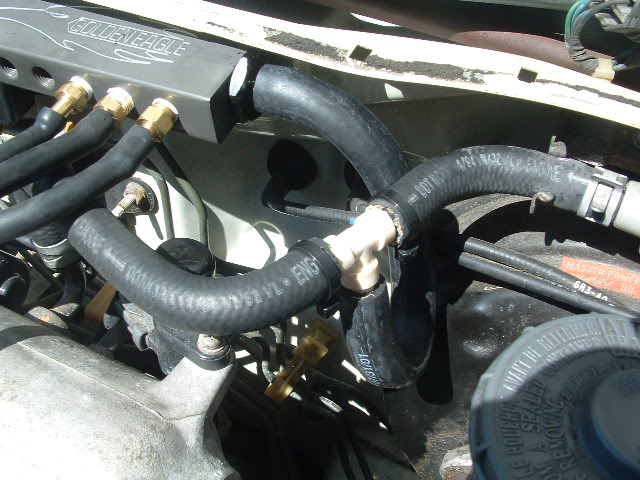

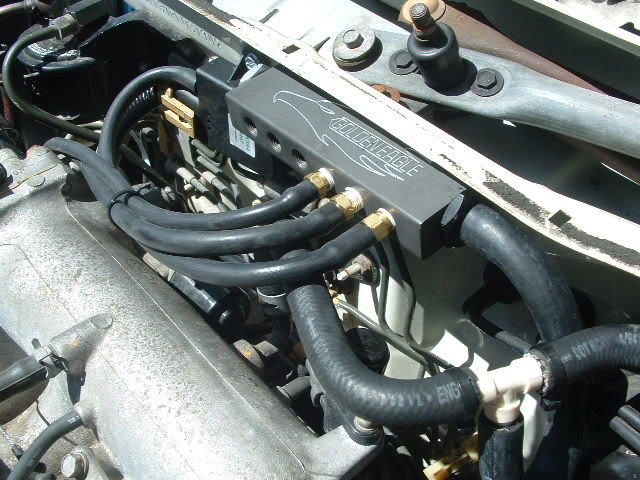

Step 10: Installing Golden Eagle Vacuum Manifold

--> Purchase a Vacuum manifold if you want a cleaner install or need it for multiple vacuum lines. I suggest a Golden Eagle Manifold. http://www.Camp3120.com to purchase one!

--> Go to your local automotive parts store to get the vacuum fittings that are needed. You will need to buy fittings that are 1/4"npt threaded side, and 1/8" barbed size. I got three in the pic but bought another later because Advanced Auto was sold out at the time.

--> This manifold does not come Pre-drilled, that way you can choose how many holes you want open without having to purchase plugs. I needed to dril out four holes for my setup. Using a 5/16th drill bit, Drill out the amount of hole that you will be using for your setup. Try not to hit the threads on the side's of the holes. Once you make it through, blow out any scrapes of metal.

--> Use teflon tape and wrap it around the threads of the fitting to insure tight seal with manifold. Screw them in and tighten them up with a wrench

--> Now is the time to find a place to mount it. The location should be no more then 5" away from the main source vacuum(brake booster line). I used the center-top area on my firewall where nothing was located. Using a 15/32 bit, make two holes useing the manifold as a template before you drill.

--> To make it a nice, secure install, i went ahead and removed the upper plastic vent infront of my windshield. There are about 10 little clips that hold it on.

Hold the manifold up and tighten it down with the bolts/nuts!

--> Using a 1/2" vacuum line, measure out the distance in which it will need to be. YOu need to use a bigger vacuum "t" that can support the 1/2" diameter lines. Cut the brake booster line BEFORE the check vavle!

Cut the brake booster line BEFORE the check valve!

Run the 1/2" line from the T to the side of the Vacuum Manifold

--> Connect the rest of the normal size vacuum lines(not sure true size). These lines will run to your products that need a good vacuum source. clamp the lines on the fittings with hose clamps or zip ties.

Finished product. Clean eh?

Step 11: Installing Boost Gauge

--> Buy a boost guage of your choice, I went the way I shouldnt have, and bought a cheap ebay boost gauge. Why not buy that guage? cus of course, it's not accurate at all.. but I was in a ditch for money. It'll be changed soon enough.

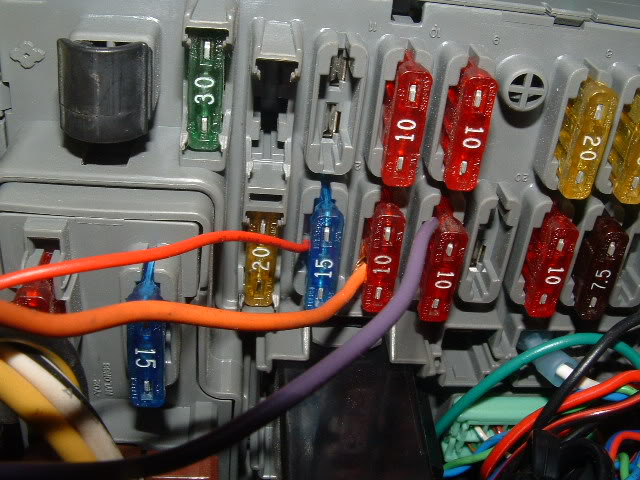

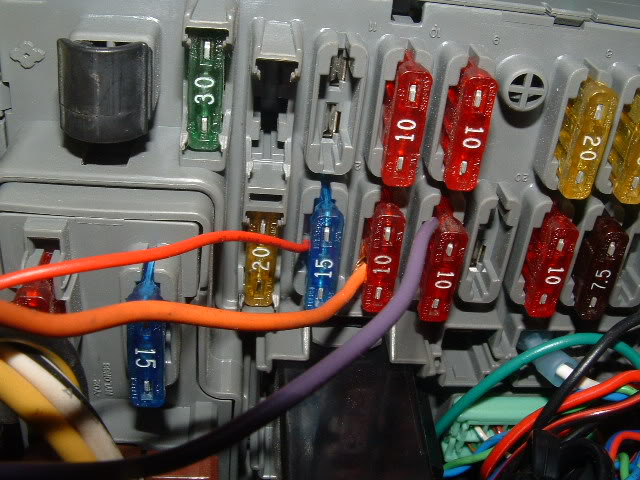

--> First, you gotta wire up your boost gauge. pwr/gnd/dim. there are plenty of ways to do this wiring, but i found the easiest way was to use your fusebox. If you take a look at the fuse box, underneath your dash, you will find exactly the sources of pwr you will need.

--> Your 12v pwr wire should plug in underneath the "radio/cigarettelighter 15a fuse" for continuous 12v action. You can plug your Dimming Control wire underneath your "low-beam" headlight fuse"

-->here they are shown pluged in... dont mind the orange wire. red is pwr, purple is dim.

--> Now it's time to run your boost/vaccum line to a vaccum source. I used my GE vaccum manifold for a good vaccum Source, make sure to tap the vaccum from the manifold side of the system so that you can read vaccum and boost. There is a small hole(just right of battery) that allows wires to travel through firewall, this is a perfect spot to feed your boost line through.

--> Keep running the line under and through the dash up to whereever you mounted your boost gauge. Pull it in and your all set to read your boost/vaccum!

-->I mounted my boost gauge on my steering column for easy viewing...

Step 12: Install Hondata Ecu

--> Easiest part of the turbo installation. LAST PART as well!

--> Move to your passenger side of the car, and pull the carpet up from underneath the dash. You wil have to pop out a few clips to get carpet up and pulled back. YOu'll see your ecu come out from hiding on the side of the wall.

--> The ecu is being held up by a few nuts/bolts. Using a 10mm take them all off and pull your ecu from it's mounted position. Now that the ecu is free from it's wall, unclip the harness from the ecu. Plug the new ecu in.. and remount it back up! Push back carpet and push back all clips!

Congratulations! You have now sucessfully installed a turbocharge in your Honda. Get ready to be boosted!!!

[b]Pre-Start Up:[b]

There are a few things you need/should do before you start it up and start driving.

--> Refill/check oil and replace oil filter

--> Flush/top off Coolant

--> Go over all electrical wiring again to make sure it's all secure and connected

--> Go over every vacuum hose to make sure it's tight and secure

--> Connect exhaust back up if you have one

--> Pull your spark plug wires and crank the motor a few times to get some oil into the brand new turbo

Start Her up!:

--> Turn the ignition and start her up!

--> Let it idle to normal operating tempatures before you drive. While it's idleing, check throughly around the oil lines to make sure there's no oil leaks.

--> Fix oil leak if necessary. and take that bitch for a test drive! no push it at ALL if it's on a basemap of some sort. If your just running a hack or fmu, take it easy till you know everything is running perfect. Drive down and back on the street, and re-check everything!

CONGRATULATIONS! YOU HAVE SUCESSFULLY INSTALLED AND DRIVEN A BOOSTED HONDA!!!!

---> now is the time to go get this Honda tuned so you can really feel boost

Written by iGfrequency(Adam)-->5/10/05

Representing and the boosted b18b ej1!

and the boosted b18b ej1!

--> First things first, you need to un-hook both negative/positive cables from the battery to be safe, cus life is better then death.

--> Next, fold down your back seat using the key lock located on your rear speaker pannel above rear seats. There is one bolt that is holding your backseats onto the chassis which is accessible through the trunk of your car. Feel free to get all the way in your trunk to ge this bolt with a wrench in hand.

--> Once that bolt is removed, go back to the inside of the car. Push the top part of the back seat back into it's locked position so you dont have it all in the way. Pull up toward you on the back seat farthest from you, you will see two metal clip that hold the front of the seat in position. Simply mouever the clips of out their holes and the back seat should come free to take out of the car.

Seat removed. Look at all that lost change! You'll find some wierd **** under your seat lol.

--> Now that you have the fuel tank access cover exposed, it's time to release fuel tank pressure. to do this, you should open up your gas cap, as well as relieve pressure from your fuel filter. Make sure you have good ventalation so you dont start tripping off gas fumes.

--> Releaseing pressure from the fuel filter is pretty easy. There is one "service" bolt that is threaded into the Banjo bolt on top of the fuel filter. Use a wrench to hold banjo bolt in place, while using a rachet to loosen the service bolt. Prepare for some fuel to leak out, so put a rag around the fuel filter.

--> It's time to take of the access cover, simple unscrewing of 4 screws will do the trick.

<

<with the cover pulled up

--> Pull out the cord from the connector first

--> use a rachet to loosen the banjo bolt (prepare for small fuel leak, have rag on hand) as well as pull vaccum hose off of the nipple. Lastly, there will be 6 nuts that hold down the cover plate, remove those.

--> NOw you are ready to pull the fuel pump out of the gas tank. Pull up and at a diagonal to remove it, should just slide out like so.

--> Once you have it out of the car, it's ready to swap the old fuel pump with the new walbro fuel pump. using a flat head screw driver, gently pop off the green "safety clip" that is holding the wire plug together. Once you poped it off, unplug the connector. Make sure not to lose the green safety clip because you will need it again to reinstall.

--> Using plyers, pull the rubber hose off the nipple. NOw the fuel pump is free to come off the mount, just pull on it and it should come off( it may feel hard to come off, but that's just cus the rubber bushing makes it have a tight fit.)

--> Compare your new walbro to your Oem fuel pump to make sure everything looks the same. In my case, the company i ordered from did not send me the correct filter to for my application, so I had no choice but to re-use the stock filter.

--> For reinstallation, just do all removal backwards. snap fuel pump into mount, connect rubber hose to nipple, plug connector back into place, snap "safety clip" onto the connector, slide fuel pump down and diagonal into fuel tank, hook up rubber hose, tighten banjo bolt, plug wire connector, tighten 6 nuts to fuel plate, screw down fuel tank access plate back down tight, clip back seats back into chassis, tighten back seat bolt. COMPLETE

Step 7: Installing Dsm Injectors

-->Buy a set of dsm injectors

-->First, relieve fuel pressure just like you did while installing the fuel pump, if not relieved already.

--> Using a flat head screwdriver, you can unclip the metal wire that holds the injector clips onto the stock injectors.

--> Take a 10mm socket with an extension on it, loosen and remove the three nut that hold the fuel rail down to the manifold.

--> The fuel rail should now be able to pulled off. When the injectors slip out of the manifold, there will be two o-rings below it, make sure you dont loose them. The injectors pop right out of the fuel rail. Here is the stock injectors(brown) compared to the dsm injectors(blue)

--> Cut the two wires leading to the stock injector clips, leave enough wire on either side so that you can rewrire the stock clips back in if you need/want to.

Strip the two wires

--> The four pairs wires coming off the fuel rail will have a common color of wire and one random color wire. If you look at the dsm clips, it will also have one common color wire and one random color wire.

The fuel rail has common yellow/black wire, and the dsm has common red wire. Take the common from each side, and solder them together for each clip. Then take the random wires and solder those together. order does not matter.

SOlder the wires together and use electrical tape to cover and protect the exposed wire.

-->Now that the clips are on, it's on to perparing the o-rings for installation. The tip of the injector on the dsm is wider in diameter then the stock injectors. This means you need to either buy larger o-ring injectors, or bore out the o-rings to fit.

Here is an side by side comparison of the diameter difference.

--> I decided to bore out the o-rings due to time constraint. I happened to have the perfect dremel bit to do the job.

--> I only used the larger hard o-ring because the soft ones would not work with the dremel. I HAVE NOT had any leaks by only useing large o-ring.

--> Install the injectors just like you took them out. tighten down 3 nuts to hold fuel rail in. the blue looks good.

Step 8: Installing Injector Resistor Box

--> Some obd0 Honda's and some other cars use low impedance injectors which need a resistor box. You can find these at a junk yard or for cheap on ebay.

--> On obd1 Honda's, there is a "dead end" clip on the wiring harness in the right corner of the engine bay. (obd2 has this clip under the intake manifold). This clip has the electrical power running through it that goes to the injectors. It is right next to the clutch master cylinder.

When you find the clip, pop off the Protecting cover so it exposes the inside.

--> Using a multimeter, check for conductivity between each clip and the end's of the "dead-end" connector. The idea is to find which wires actually are routed to the injector clips, so seeing if electricity can flow, you can guess-and-check and find out.

There are eight different wires going into the "dead-end" connector, all of which you must check to see if they are the winners! According to h-t, it could be random placed, so do not assume and follow my example. CHECK FOR YOURSELF TO MAKE SURE!

The red dots are showing which ones came out conductive for me. AGAIN, CHECK FOR YOURSELF TO MAKE SURE!

--> Once you found out which ones are conductive, move down 2-4 inches and cut the wire. This break in to wire is where you will have your resistor tie into the system. Strip both sides of the new striped wires.

--> If you take a look at your resistor box, there should be 5 wires coming out of it. Four of them should be common color and one of them should be a different color. Strip all the ends if they are not already.

--> Next, Take the Single different color wire from the resistor box and solder it to all Four of the wires on the "dead-end" side. See diagram for better explaintion.

Connect Each one of the Four common color wires from the resistor box to one of the four yellow/black wires on the Injector side of the cut. Solder each wire seperately, no order is nessecary.

Here is a Diagram I made for better explaintion.

--> Wrap all the exposed wires up with electrical tape and mount the resistor box in the corner. here is the finished product.

Step 9: Installing Gm 3bar Map Sensor

--> Purchase Gm 3bar Map Sensor with Pigtail connector From Camp1320.com. It's like 80$shipped new!

--> You must find stock map sensor(it is located right ABOVE throttle body). Clip off the old connector on the harness side of the sensor. Strip and get the wires ready to solder to somethign new.

--> The new Gm map sensor should have came with a "pigtail" which is the male side of the connector with wires coming out of it ready to solder together. Strip them.

--> I put together a diagrahm on how this should be wired up!

Refrence hondata.com's picture of a gm 3bar for the clip wire order...

--> Connect a vacuum hose from the map sensor to a good vacuum source. I used a GE vac manifold again for a good relieable source. You do not want to "t" this vacuum source off anything else, nor have it too long of a hose. The map sensor is sensitive and extremely important to the performance of your vehicle.

--> To check for proper installation, use multimeter to check voltages and conductivity. Between wire A and C, there should read 5volts. With ignition "on" but car not running, There should be 1.6Volts between A(GND) and B(map signal).

Step 10: Installing Golden Eagle Vacuum Manifold

--> Purchase a Vacuum manifold if you want a cleaner install or need it for multiple vacuum lines. I suggest a Golden Eagle Manifold. http://www.Camp3120.com to purchase one!

--> Go to your local automotive parts store to get the vacuum fittings that are needed. You will need to buy fittings that are 1/4"npt threaded side, and 1/8" barbed size. I got three in the pic but bought another later because Advanced Auto was sold out at the time.

--> This manifold does not come Pre-drilled, that way you can choose how many holes you want open without having to purchase plugs. I needed to dril out four holes for my setup. Using a 5/16th drill bit, Drill out the amount of hole that you will be using for your setup. Try not to hit the threads on the side's of the holes. Once you make it through, blow out any scrapes of metal.

--> Use teflon tape and wrap it around the threads of the fitting to insure tight seal with manifold. Screw them in and tighten them up with a wrench

--> Now is the time to find a place to mount it. The location should be no more then 5" away from the main source vacuum(brake booster line). I used the center-top area on my firewall where nothing was located. Using a 15/32 bit, make two holes useing the manifold as a template before you drill.

--> To make it a nice, secure install, i went ahead and removed the upper plastic vent infront of my windshield. There are about 10 little clips that hold it on.

Hold the manifold up and tighten it down with the bolts/nuts!

--> Using a 1/2" vacuum line, measure out the distance in which it will need to be. YOu need to use a bigger vacuum "t" that can support the 1/2" diameter lines. Cut the brake booster line BEFORE the check vavle!

Cut the brake booster line BEFORE the check valve!

Run the 1/2" line from the T to the side of the Vacuum Manifold

--> Connect the rest of the normal size vacuum lines(not sure true size). These lines will run to your products that need a good vacuum source. clamp the lines on the fittings with hose clamps or zip ties.

Finished product. Clean eh?

Step 11: Installing Boost Gauge

--> Buy a boost guage of your choice, I went the way I shouldnt have, and bought a cheap ebay boost gauge. Why not buy that guage? cus of course, it's not accurate at all.. but I was in a ditch for money. It'll be changed soon enough.

--> First, you gotta wire up your boost gauge. pwr/gnd/dim. there are plenty of ways to do this wiring, but i found the easiest way was to use your fusebox. If you take a look at the fuse box, underneath your dash, you will find exactly the sources of pwr you will need.

--> Your 12v pwr wire should plug in underneath the "radio/cigarettelighter 15a fuse" for continuous 12v action. You can plug your Dimming Control wire underneath your "low-beam" headlight fuse"

-->here they are shown pluged in... dont mind the orange wire. red is pwr, purple is dim.

--> Now it's time to run your boost/vaccum line to a vaccum source. I used my GE vaccum manifold for a good vaccum Source, make sure to tap the vaccum from the manifold side of the system so that you can read vaccum and boost. There is a small hole(just right of battery) that allows wires to travel through firewall, this is a perfect spot to feed your boost line through.

--> Keep running the line under and through the dash up to whereever you mounted your boost gauge. Pull it in and your all set to read your boost/vaccum!

-->I mounted my boost gauge on my steering column for easy viewing...

Step 12: Install Hondata Ecu

--> Easiest part of the turbo installation. LAST PART as well!

--> Move to your passenger side of the car, and pull the carpet up from underneath the dash. You wil have to pop out a few clips to get carpet up and pulled back. YOu'll see your ecu come out from hiding on the side of the wall.

--> The ecu is being held up by a few nuts/bolts. Using a 10mm take them all off and pull your ecu from it's mounted position. Now that the ecu is free from it's wall, unclip the harness from the ecu. Plug the new ecu in.. and remount it back up! Push back carpet and push back all clips!

Congratulations! You have now sucessfully installed a turbocharge in your Honda. Get ready to be boosted!!!

[b]Pre-Start Up:[b]

There are a few things you need/should do before you start it up and start driving.

--> Refill/check oil and replace oil filter

--> Flush/top off Coolant

--> Go over all electrical wiring again to make sure it's all secure and connected

--> Go over every vacuum hose to make sure it's tight and secure

--> Connect exhaust back up if you have one

--> Pull your spark plug wires and crank the motor a few times to get some oil into the brand new turbo

Start Her up!:

--> Turn the ignition and start her up!

--> Let it idle to normal operating tempatures before you drive. While it's idleing, check throughly around the oil lines to make sure there's no oil leaks.

--> Fix oil leak if necessary. and take that bitch for a test drive! no push it at ALL if it's on a basemap of some sort. If your just running a hack or fmu, take it easy till you know everything is running perfect. Drive down and back on the street, and re-check everything!

CONGRATULATIONS! YOU HAVE SUCESSFULLY INSTALLED AND DRIVEN A BOOSTED HONDA!!!!

---> now is the time to go get this Honda tuned so you can really feel boost

Written by iGfrequency(Adam)-->5/10/05

Representing

and the boosted b18b ej1!

and the boosted b18b ej1!

Thread

Thread Starter

Forum

Replies

Last Post